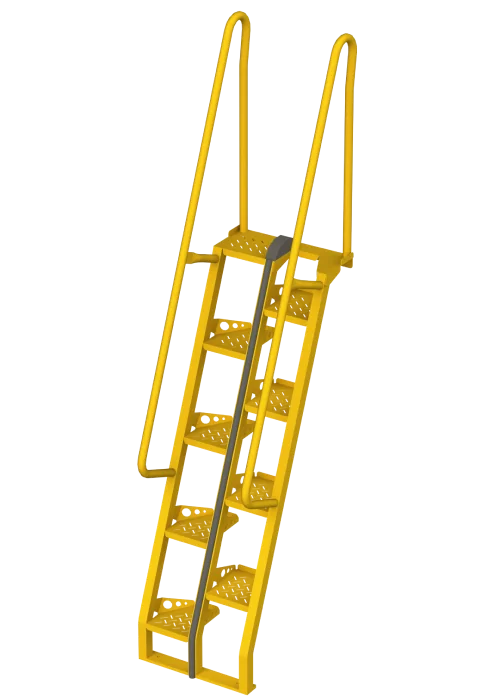

Alternating Tread Stairs

A safer alternative to ships ladders that provides maximum safety, minimum space. With lead times as fast as 3-days for powder-coated carbon steel stairs.

Alternating Tread Stairs

The Original Lapeyre Alternating Tread Stair provides maximum safety, minimum space.The Original Lapeyre Alternating Tread Stair

Since 1981, our patented alternating tread stair design has set the industry standard for safe, ergonomic, compliant industrial access.

Maximum Safety. Minimum Space.

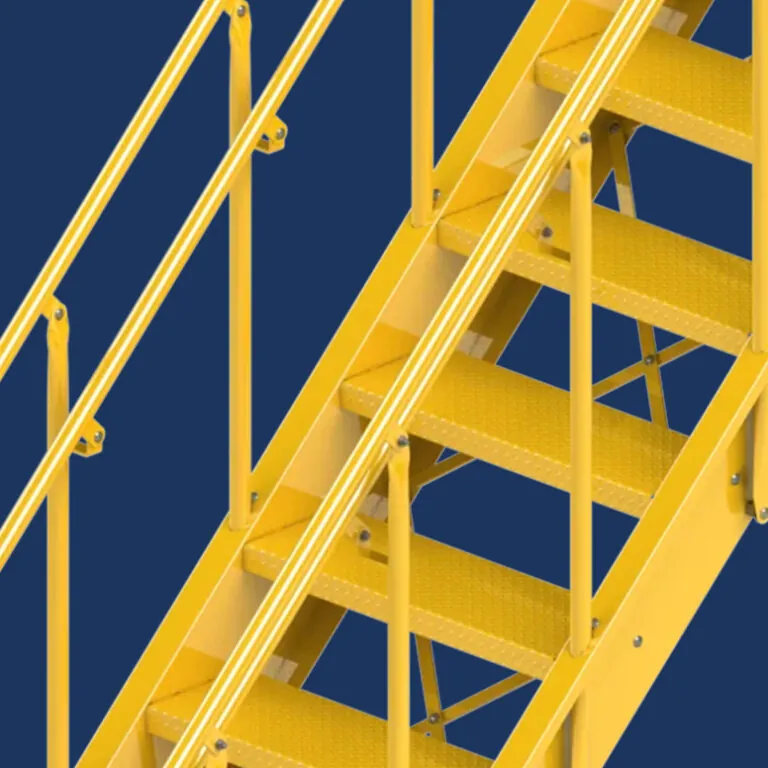

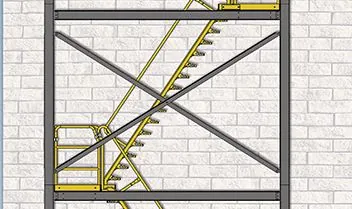

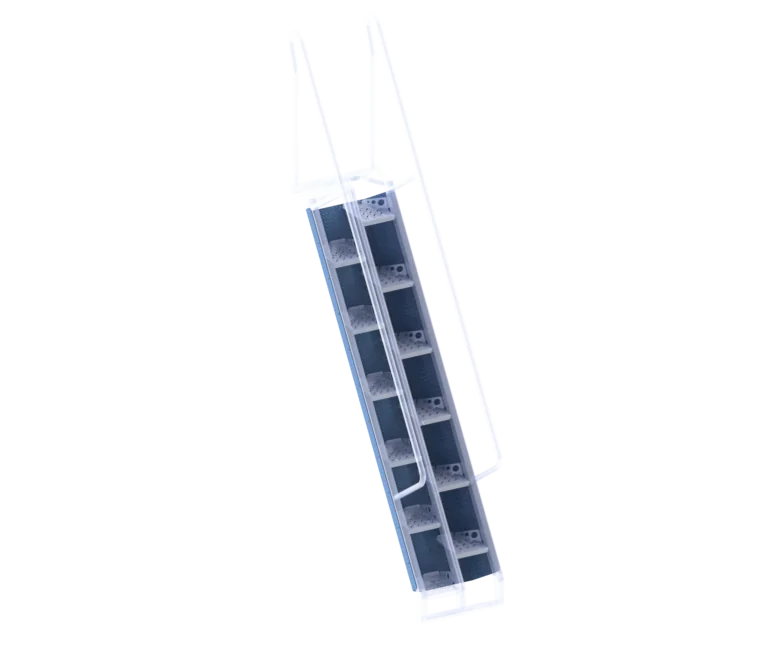

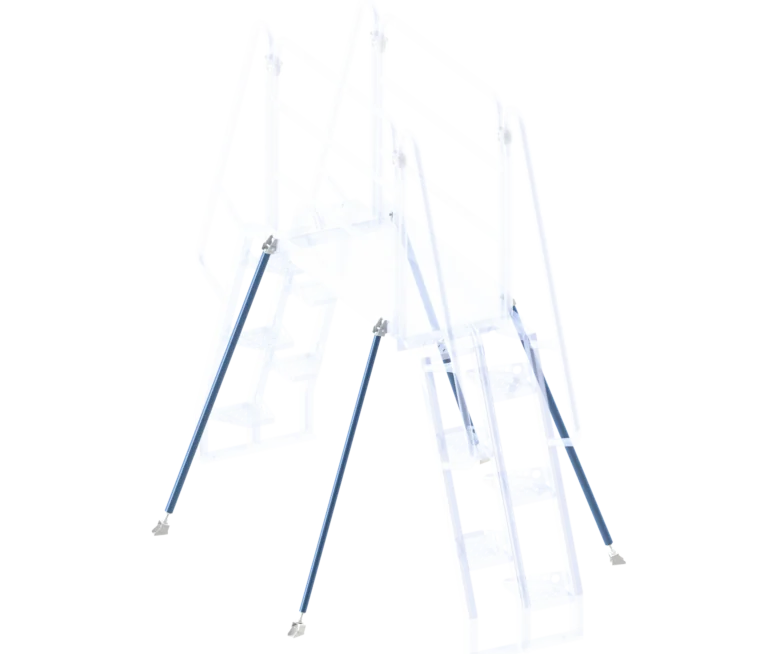

Alternating tread stairs require a smaller overall footprint than standard stairs because of their steeper slope of either 56 or 68 degrees

Alternating tread stairs are designed to be used as a standard stair with users facing the direction of travel when climbing up and down.

Our experts will make sure your alternating tread stars are designed and engineered to meet OSHA and IBC requirements.

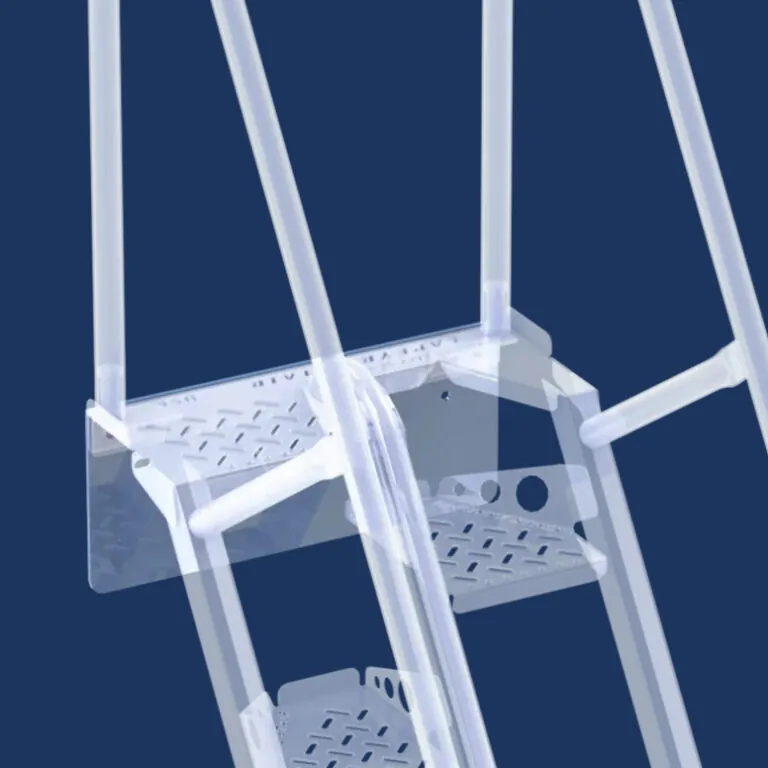

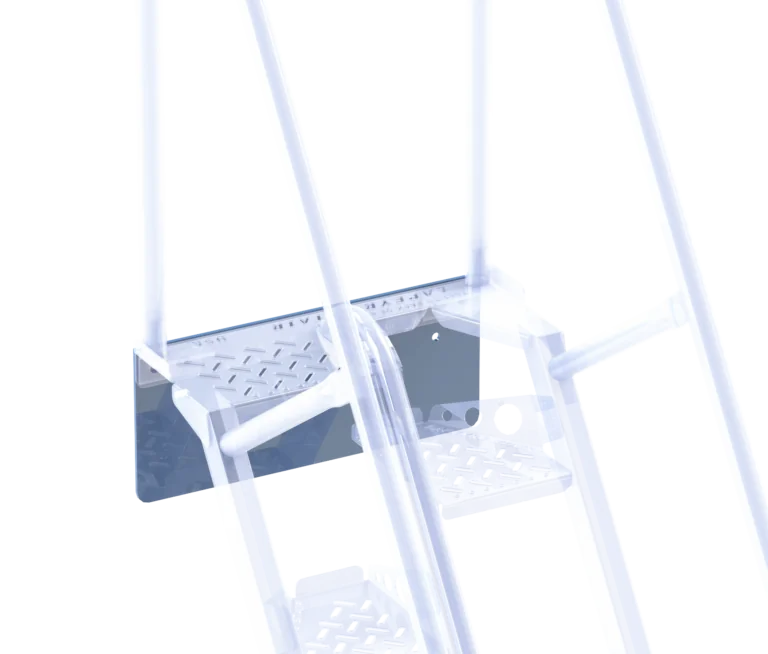

Alternating tread stairs have a built-in, cushioned, central stringer designed to protect users and reduce the risk of trips and falls

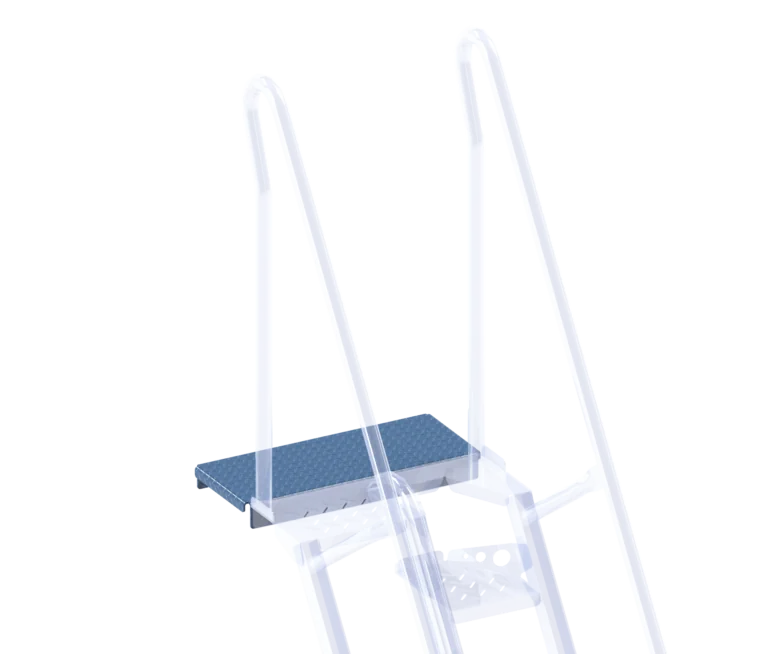

The 8 1/2" tread depths on the alternating tread stair gives users firm, full-footed support.

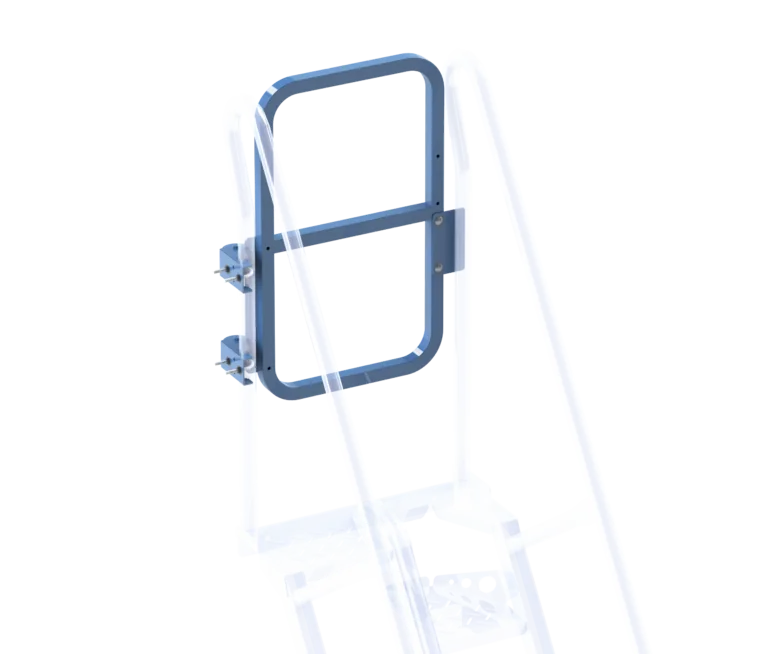

The code-compliant handrails on alternating tread stairs meet OSHA requirements for fall protection and improve ease of use

Alternating Tread Stair Code Compliance

OSHA Compliance

Alternating tread stairs are allowed when a standard stair is not feasible for regular and routine travel between levels, including access to operating platforms for equipment.

IBC Compliance

Alternating tread stairs are allowed as a means of egress from small mezzanines, guard towers, observation stations, control rooms, and as access to unoccupied roofs.

Comparisons

When placed against standard industrial stairs, ships stairs, and fixed vertical ladders, the alternating tread stair is the safe alternative when space is at a premium

OSHA classifies alternating tread stairs (alternating tread devices) as non-standard stairs and states they are acceptable to use in applications where it is not feasible to use standard stairs.

Versus a Standard Industrial Stair

Less space? Choose an alternating tread stair for applications where space is limited. The 68° alternating tread stairs require the least amount of space but the steeper angle is less comfortable to use. The less steep angle of 56° alternating tread stairs is more comfortable to use while also requiring less space.

Versus a Ships Stair

Virginia Tech conducted a study comparing alternating tread stairs to ship stairs and concluded that alternating tread stairs have a clear comfort and safety advantage over ship stairs.

Versus a Fixed Ladder?

Ladders are consistently one of OSHA's top ten most cited violations for general industry. The need to address the hazard they present in the workplace was one of the reasons for the 2017 update to the Walking-Working Surfaces standard. Source: Federal Registry, Vol. 61, No. 223

Ladders and fall injuries, musculoskeletal disorders

The National Institute for Occupational Safety and Health defines musculoskeletal disorder (MSD) as a soft-tissue injury caused by sudden or sustained exposure to repetitive motion, force, vibration, and awkward positions.

Instructions, Drawings, Designs, Specs

Search alternating tread specifications, data sheets, design, technical, installation files

Measuring guidelines, sample prints, standard dimensions, connection details, and more.

Space Savings vs. Standard Industrial Stair

| VERTICAL HEIGHT/RISE | HORIZONTAL RUN | ||

| STEEL, 56° | STEEL, 68° | STANDARD STAIR | |

| 4' | 3'11" | 2'2" | 4'3" |

| 6' | 4'5" | 2'11" | 5'10" |

| 8' | 5'9" | 3'9" | 8'2" |

| 10' | 7'1" | 4'7" | 9'9" |

| 12' | 8'6" | 5'4" | 12'2" |

| 14' | 9'10" | 6'2" | 13'9" |

| 16' | 11'2" | 7' | 16'1" |

| 18' | 12'6" | 7'10" | 17'8" |

| 20' | 13'10" | 8'7" | 20'1" |

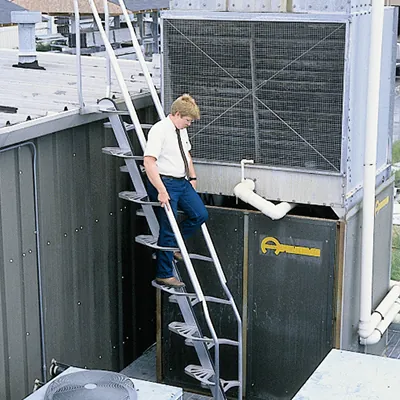

Alternating Tread Stair Applications

The Alternating Tread Stair In Use

Alternating Tread Stair Options, Materials and Finishes

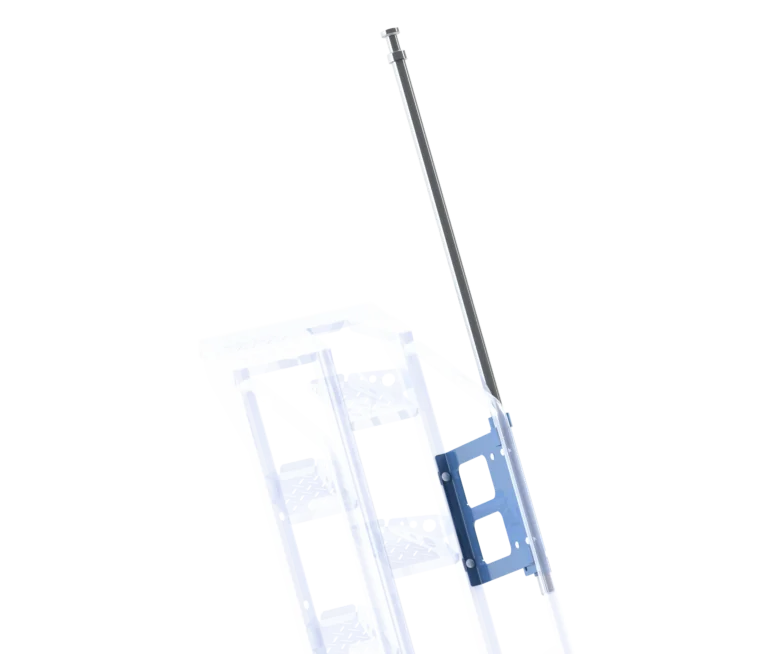

Handrail Options

| Heights | Angles | Handrails | ||||||

| Min | Max (Single Run) | 56° | 68° |  |  |  | ||

| Powder Coated Carbon Steel | 36" | 240" |  |  |  |  |  | |

| Galvanized Carbon Steel | 36" | 240" |  |  |  |  |  | |

| Stainless Steel | 36" | 240" |  |  |  |  |  | |

| Aluminum Steel | 24" | 216" |  |  |  | |||

Powder Coated Carbon Steel

Our most popular and most used type of alternating tread stair Ideal for most indoor applications.

Design Specifications & Options

Hot Dipped Galvanized Carbon Steel

Carbon steel alternating tread stairs with a galvanized finish, ideal for outdoor applications.

Design Specifications & Options

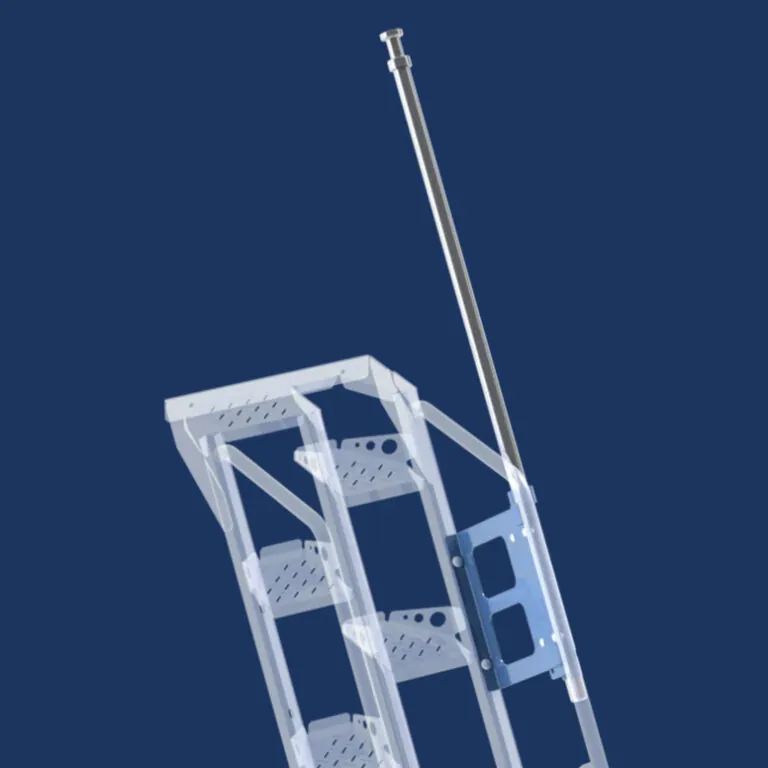

Stainless Steel

Ideal for food processing and sanitary conditions.

Ideal for food processing and sanitary conditions.

Design Specifications & Options

Aluminum

About aluminum alternating tread stairs

Design Specifications & Options